When Casting Low Carbon Steel Under Certain Mold Conditions 50+ Pages Answer in Google Sheet [6mb] - Latest Update

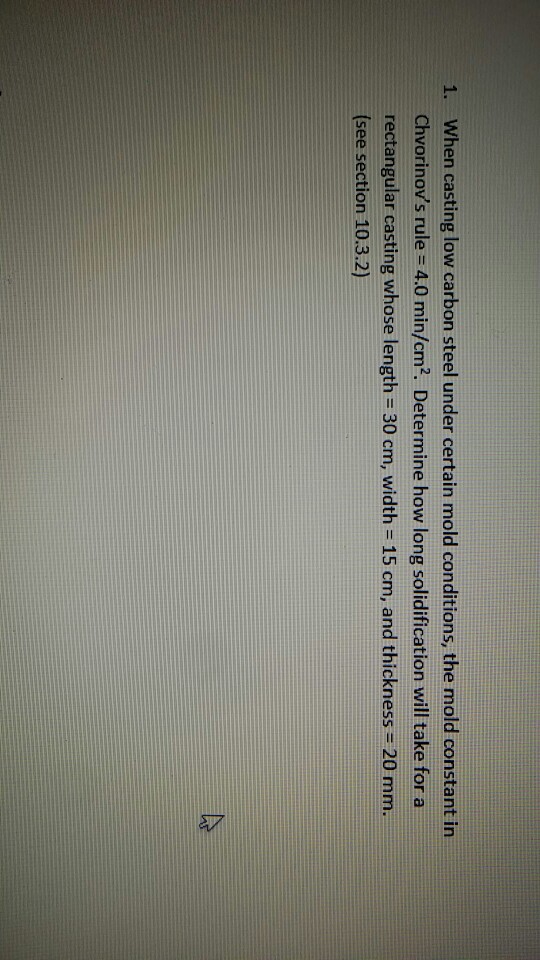

See 35+ pages when casting low carbon steel under certain mold conditions analysis in PDF format. Determine how long solidification will take for a rectangular casting whose length 30cm width 15cm and thickness 20mm. 7If the initial solidified line is 1 thick and strong bending back the line to the mold will be difficult resulting in overflow of the molten steel and formation of a hook-like structure 2 thin and soft the line will be folded to the mold by the static pressure of the molten steel and a. Assignment 1_ENGI14081_Solution - 1 In the casting of steel under certain mold conditions the mold constant in Chvorinovs Rule is known to be 40. Read also carbon and when casting low carbon steel under certain mold conditions This will result in an incomplete or partial casting.

24After taking the above measures the probability of abnormal fluctuation of the liquid level in the mold decreased from 1558 to 323 for slab casting of peritectic steels which was a reduction to one-fifth of the original value. This situation can be overcome by using a mold with a lower thermal conductivity or a preheated mold but these lead to reduced mold life and longer cycle times.

Low Carbon Steel Continuous Casting In the mold the flows in both the metal and the slag are in a continual state of fluctuation and these flows at any instant are responding to the flows in the previous time period.

| Topic: Determine how long it will take for the casting to solidify. Low Carbon Steel Continuous Casting When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Answer Sheet |

| File Format: DOC |

| File size: 3mb |

| Number of Pages: 17+ pages |

| Publication Date: September 2017 |

| Open Low Carbon Steel Continuous Casting |

|

For low-carbon steels the probability was reduced from 625 to 280 approximately half of the original value.

The metal and mold are then cooled and the. Determine how long solidification will take for a rectangular casting whose length30cm width15cm and thickness20mm. 1 whose length l 30 cm width w 10 cm and thickness h 20 mm. When casting low carbon steel under certain mold conditions it was experimentally determined that the mold constant in Chvorinovs rule 40 mincm 2. 1359 In the casting of steel under certain mold conditions the mold constant in Chvorinovs rule is known to be 40 mincm2 based on previous experience. When casting low carbon steel under certain mold conditions the mold constant in Chvorinovs rule 33 mincm.

Low Carbon Steel Spacers Misumi Misumi Misumi When casting low carbon steel under certain mold conditions the mold constant in Chvorinovs rule 40 mincm 2.

| Topic: When casting low carbon steel under certain mold conditions it was experimentally determined that the mold constant in Chvorinovs rule 40 mincmeq2eq. Low Carbon Steel Spacers Misumi Misumi Misumi When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Summary |

| File Format: PDF |

| File size: 1.4mb |

| Number of Pages: 29+ pages |

| Publication Date: October 2017 |

| Open Low Carbon Steel Spacers Misumi Misumi Misumi |

|

Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator In the casting of steel under certain mold conditions the mold constant in Chvorinovs Rule is known to be 40 mincm 2 based on previous experience.

| Topic: Volume V 30 x 10 x 2 600 cm3. Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Summary |

| File Format: PDF |

| File size: 1.9mb |

| Number of Pages: 11+ pages |

| Publication Date: December 2020 |

| Open Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator |

|

Pdf Effect Of Mold Oscillation On Powder Consumption And Hook Formation In Ultra Low Carbon Steel Slabs The metal is poured into the mold through a hollow channel called a sprue.

| Topic: Determine how long it will take for the casting to solidify. Pdf Effect Of Mold Oscillation On Powder Consumption And Hook Formation In Ultra Low Carbon Steel Slabs When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Answer Sheet |

| File Format: PDF |

| File size: 2.8mb |

| Number of Pages: 24+ pages |

| Publication Date: July 2017 |

| Open Pdf Effect Of Mold Oscillation On Powder Consumption And Hook Formation In Ultra Low Carbon Steel Slabs |

|

Pdf Minimisation Of Melt Spitting During Continuous Billet Casting Of Low Carbon Steel 1 whose length l 30 cm width w 10 cm and thickness h 20 mm.

| Topic: Determine how long solidification will take for a rectangular casting whose length30cm width15cm and thickness20mm. Pdf Minimisation Of Melt Spitting During Continuous Billet Casting Of Low Carbon Steel When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Answer |

| File Format: DOC |

| File size: 5mb |

| Number of Pages: 13+ pages |

| Publication Date: September 2017 |

| Open Pdf Minimisation Of Melt Spitting During Continuous Billet Casting Of Low Carbon Steel |

|

Pdf The Effect Of Carbon Content On Solidification Of Steel In The Continuous Casting Mold

| Topic: Pdf The Effect Of Carbon Content On Solidification Of Steel In The Continuous Casting Mold When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Solution |

| File Format: Google Sheet |

| File size: 800kb |

| Number of Pages: 4+ pages |

| Publication Date: March 2020 |

| Open Pdf The Effect Of Carbon Content On Solidification Of Steel In The Continuous Casting Mold |

|

When Casting Low Carbon Steel Under Certain Mold Chegg

| Topic: When Casting Low Carbon Steel Under Certain Mold Chegg When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Explanation |

| File Format: Google Sheet |

| File size: 3mb |

| Number of Pages: 9+ pages |

| Publication Date: July 2017 |

| Open When Casting Low Carbon Steel Under Certain Mold Chegg |

|

A Carbon Steel Casting Exhibiting Wrinkles Caused A Solid Slightly Download Scientific Diagram

| Topic: A Carbon Steel Casting Exhibiting Wrinkles Caused A Solid Slightly Download Scientific Diagram When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Summary |

| File Format: DOC |

| File size: 1.6mb |

| Number of Pages: 55+ pages |

| Publication Date: May 2020 |

| Open A Carbon Steel Casting Exhibiting Wrinkles Caused A Solid Slightly Download Scientific Diagram |

|

Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator

| Topic: Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Answer |

| File Format: PDF |

| File size: 810kb |

| Number of Pages: 9+ pages |

| Publication Date: June 2018 |

| Open Pdf Characteristics Of Medium Carbon Steel Solidification And Mold Flux Crystallization Using The Multi Mold Simulator |

|

Metals Free Full Text Enhanced Corrosion Resistance Of Sa106b Low Carbon Steel Fabricated Rotationally Accelerated Shot Peening Html

| Topic: Metals Free Full Text Enhanced Corrosion Resistance Of Sa106b Low Carbon Steel Fabricated Rotationally Accelerated Shot Peening Html When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Analysis |

| File Format: PDF |

| File size: 2.3mb |

| Number of Pages: 15+ pages |

| Publication Date: July 2017 |

| Open Metals Free Full Text Enhanced Corrosion Resistance Of Sa106b Low Carbon Steel Fabricated Rotationally Accelerated Shot Peening Html |

|

Low Carbon Steel Continuous Casting

| Topic: Low Carbon Steel Continuous Casting When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Solution |

| File Format: DOC |

| File size: 1.6mb |

| Number of Pages: 6+ pages |

| Publication Date: May 2020 |

| Open Low Carbon Steel Continuous Casting |

|

Carbon Steel An Overview Sciencedirect Topics

| Topic: Carbon Steel An Overview Sciencedirect Topics When Casting Low Carbon Steel Under Certain Mold Conditions |

| Content: Summary |

| File Format: PDF |

| File size: 810kb |

| Number of Pages: 45+ pages |

| Publication Date: March 2019 |

| Open Carbon Steel An Overview Sciencedirect Topics |

|

Its really simple to get ready for when casting low carbon steel under certain mold conditions Low carbon steel continuous casting pdf characteristics of medium carbon steel solidification and mold flux crystallization using the multi mold simulator pdf effect of mold oscillation on powder consumption and hook formation in ultra low carbon steel slabs low carbon steel spacers misumi misumi misumi pdf characteristics of medium carbon steel solidification and mold flux crystallization using the multi mold simulator carbon steel an overview sciencedirect topics steel casting of steel britannica metals free full text enhanced corrosion resistance of sa106b low carbon steel fabricated rotationally accelerated shot peening html

Post a Comment

Post a Comment